(Originally Published on or Prior to 1998)

At Simplex Filler Company, Hayward, California, the name of the game is safety, timing and precision. Clippard modular valves play an important role in controlling the reliability and quality of automatic battery filling where a corrosive sulphuric acid is involved.

Simplex Filler Company is a 40-year-old West Coast firm which designs and builds a wide variety of filling machines for the food, pharmaceutical, cosmetic and chemical industries. These are piston, pressure or vacuum filling machines that can handles all types of fluids from thin to very viscous with excellent accuracy.

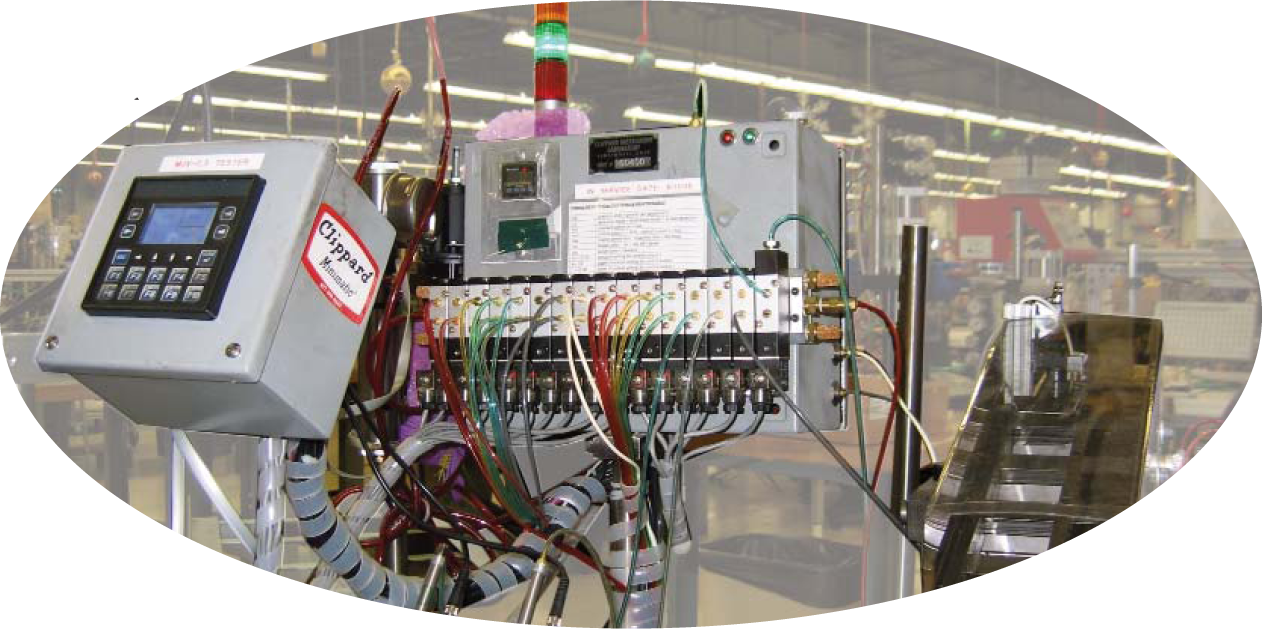

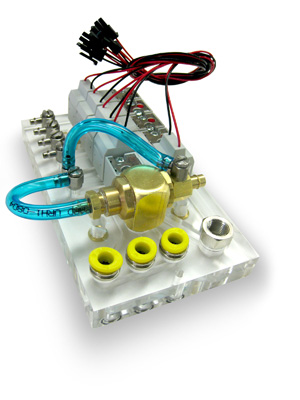

While Clippard products are part of nearly every unit built by the company, one of the most interesting applications is the modular control system on the Simplex BF-400 fully automatic battery filler. Although basically a standard machine, it is adjustable to accommodate a wide range of battery sizes at a rate of up to six per minute.

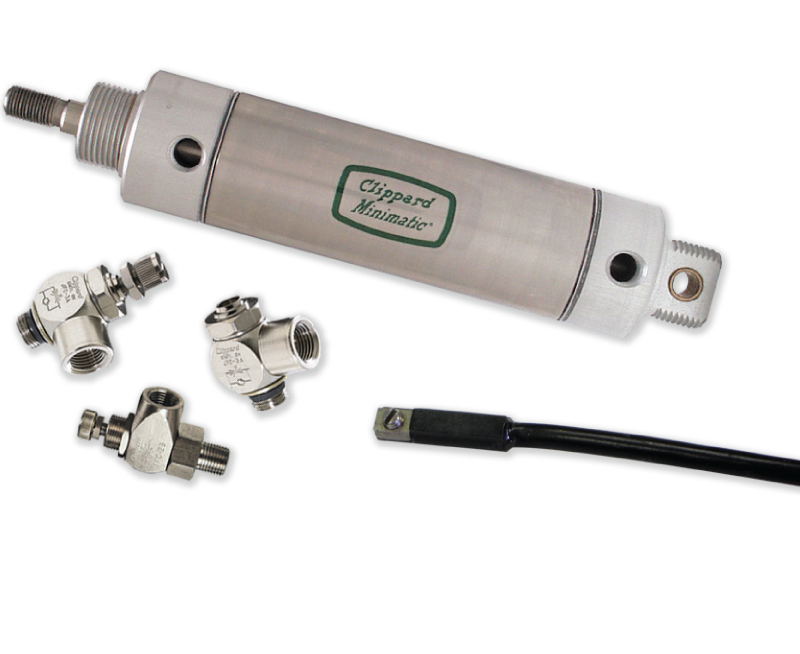

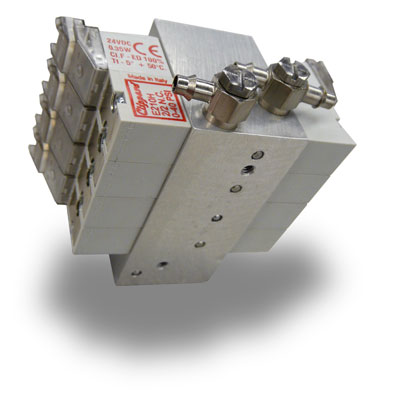

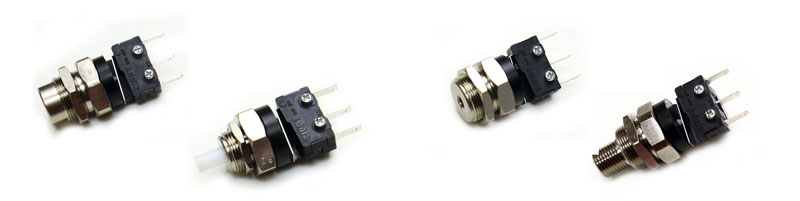

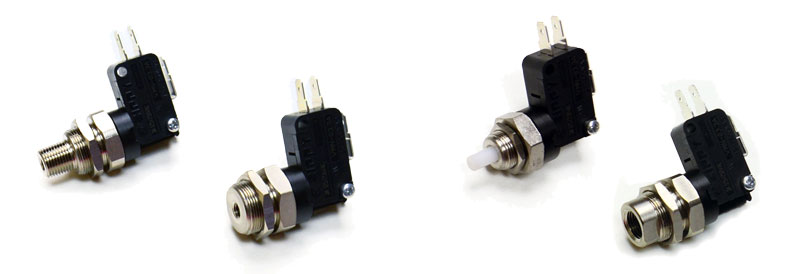

The Clippard pneumatic control system consists of 18 modular valves, LVA limit switches, toggle switches, MPA-7 pilot actuators, cylinders, plus hose and fittings. The logic controls are encased in an air-tight enclosure for maximum protection in any corrosive atmosphere.

The application operates as follows…

Empty batteries continuously move along an infeed conveyor at random, then enter onto the BF-400 conveyor where they are positioned, two at a time, under the 12 filling spouts (six per battery). They are exactly spaced by pneumatic indexers to unsure proper position, since filling can occur only when two batteries are in place at a time.

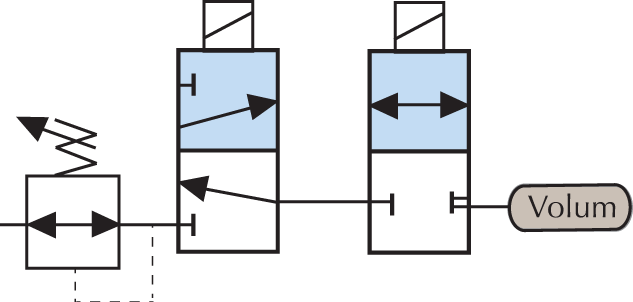

The control system now activates, lowering the head spouts in to the battery cells. A vacuum is created and all air is evacuated from the cells. After each cells is filled with a sulphuric acid solution, the filling spouts pull away from the battery.

At the same time, the vacuum process begins again to eliminate any drippage from the spouts. The pneumatic indexers are retracted, the filled batteries move out and another pair of batteries is positioned in the same manner.

Individual cell overfill is controlled by a pneumatic timer and any overflow is automatically returned to a supply tank at the rear of the machine.

If, for some reason, there is not the proper vacuum in a cell during the filling process, filling will not occur and an alarm will sound, signifying there is an unfilled battery. This quality control measure occurs even if one battery is filled, and the other is not.

Among the important safety features of the machine as a container holding an alkali and reagent solution designed to protect the vacuum pump. If the solution becomes too acid, it turns bright red and a check valve in the jar prevents the solution from backing up into the pump. Also, if the jar fills to an unsafe level, an automatic shutoff occurs.

Because of obvious corrosive conditions, the BF-400 has a stainless steel frame with an acid resistant coating, and an acid resistant conveyor chain.

John E. Copeland, Simplex vice president, said this totally automatic filling system replaced an old-fashioned manual system… and has greatly added to the overall safety of the operation. The initial BF-400 with the Clippard modular control panel was shipped in October, 1977 and, according to Copeland, has served to create a potential market for this type of machine.

Copeland adds, “We are especially pleased with the Clippard modular system because of its reliability, simplicity and ease of valve replacement. Our maintenance has been kept to a minimum since we became a Clippard customer. We could literally return the entire circuit box for replacement if necessary.

The logic design of the successful BF-400 modular control system was accomplished by Everett Stehn, engineering manager, and Loren Bart, systems engineer, of Bay Pneumatic, Inc., Clippard distributor head-quartered in the San Francisco area. Copeland emphasized that Bay Pneumatic was highly instrumental in designing the proper circuit for this particular operation, and thus getting the machine into the marketplace. Copeland added, “Our continuing contact with Bay from a service angle has been outstanding. They have been extremely helpful in working with us all along the way.”

Simplex Filler Company was founded in nearby Sausilito in 1939, and was then known as the F.L. Burt Company. In 1996, the name was changed to Simplex Filler Company following an acquisition of the Eryle Company. The firm moved to the Mission District of San Francisco in 1945, then to its present Hayward location in October, 1978.

The company is presently headed by George C. Lydiksen, president.

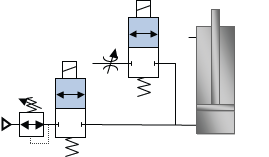

speed and orifice of the valves used in the circuit and the accuracy of a pressure transducer.

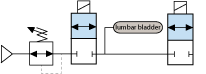

speed and orifice of the valves used in the circuit and the accuracy of a pressure transducer. In lumbar support applications, pressure would be better defined as firmness, where a pneumatic fill and bleed circuit is controlling the air pressure in a flexible bladder built into a seat. Massage or therapy chairs use multiple bladders filling and bleeding pressure that changes the firmness in a sequential pattern massaging the user. These applications can be found in first-class airline seats, train seats, truck or mobile cabs where the operator is sitting for extended periods of time.

In lumbar support applications, pressure would be better defined as firmness, where a pneumatic fill and bleed circuit is controlling the air pressure in a flexible bladder built into a seat. Massage or therapy chairs use multiple bladders filling and bleeding pressure that changes the firmness in a sequential pattern massaging the user. These applications can be found in first-class airline seats, train seats, truck or mobile cabs where the operator is sitting for extended periods of time.

The lack of standardized wound therapy methods and care contributes to unnecessarily long treatment and healing times. In addition, these factors contribute to excessively high costs borne by patients and health plans. Various new technologies and discoveries are bringing to patients the ability to work with their doctors to get wounds under control with pneumatics.

The lack of standardized wound therapy methods and care contributes to unnecessarily long treatment and healing times. In addition, these factors contribute to excessively high costs borne by patients and health plans. Various new technologies and discoveries are bringing to patients the ability to work with their doctors to get wounds under control with pneumatics.

View more information

View more information